|

Introduction Part 1 of this story, in Quainton News 72, told of the trials and traumas suffered

by Dennis in acquiring his Hawksworth coach. As promised, now follows the story of the first steps on the long road to restoration...

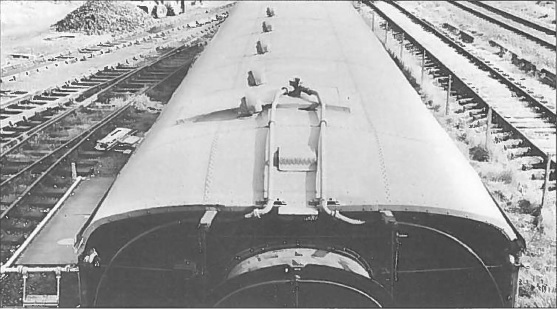

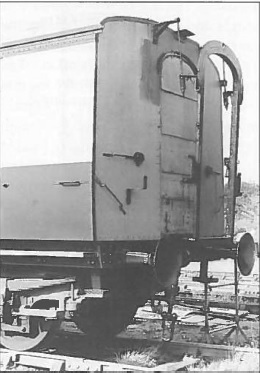

With the coach now firmly and safely located at Quainton Road, various crucial decisions had to be made about how to proceed with

the task of restoration. Dennis had gleaned from BR that the principal reason behind their decision to scrap was that the coach was very leaky!

An initial inspection revealed that the previous roof repair made by BR now needed doing again. Further, many of the steel side panels were well

past their serviceable life, and many had extra screw holes for fittings not now required, and which would anyway be incompatible with an authentic

rebuild. The decision was therefore taken tore-skin the vehicle, starting at the top where BR had made their original roof repair, down to frame level,

and including the ends. Now that this momentous decision (it promised a great deal of hard work!) had been made, it was necessary to consider the logistics

of how to re-skin the sides of a coach - in total approx. 130' - out in the open air exposed to all the vagaries of the climate of the Vale of Aylesbury.

Of course, all guttering would also need replacing. It quickly became apparent that to purchase galvanized sheet piecemeal as the pace of work demanded

would be unacceptable on grounds of cost. Fortunately, during the days of restoration of his pannier tank 9466, Dennis had forged ties with many engineering

firms, and through this network was able to find a local firm who offered to supply and store ordered galvanized sheets alongside their own. Dennis was

thus able to buy all the sheetwork in one go and at an attractive price, for the firm was able to combine this bulk order with their own annual one.

Together with his father, the late Brynley Howells, Dennis started the daunting task by deskinning one-third of the length of the coach, boarding in

with hardboard to keep out the elements. By doing the work on a rolling basis, frugal Dennis was able to make the boards last the entire job, moving

them on section by section.

Further 'systems analysis' of the task led to the inescapable conclusion that to finish the re-skin to any reasonable timescale, it

would not be possible to do all the preparation at Quainton. The panels were therefore taken to the Howells home in Harrow to be cut to shape, drilled,

countersunk etc. in Dennis's back garden. (Dennis wonders, tongue-in-cheek, how much his mother and neighbours must have enjoyed this - it went on for

years!) The prepared panels were painted on both sides, numbered and brought back to Quainton for fitting. This arrangement allowed work to take place

off site Monday to Friday, leaving the weekends for work on the vehicle itself which of course couldn't be taken home!

|