BRC Website Home

Quainton Virtual Stockbook

Quainton News Archive - Quainton News No. 73 - September 1993

BR(WR) Modified Hall Class 4-6-0 No. 6989 Wightwick Hall

6989 - Progress Report

BRC Website Home

Quainton Virtual Stockbook

Quainton News Archive - Quainton News No. 73 - September 1993

BR(WR) Modified Hall Class 4-6-0 No. 6989 Wightwick Hall

6989 - Progress Report

|

At the end of my last report (Quainton News 72) I indicated that Bob Judge would be coming to trace accurately the tyre profile of the coupled wheelsets of Wightwick Hall. The prognosis was unfortunately every bit as bad as we had all feared: all but one tyre is so badly worn that to turn them to the specified BR profile would reduce the tyre thickness to the scrapping limit. Therefore there are only two roads down which to go: either run the loco on its present tyres on preserved lines (they are perfectly adequate for this on their present profiles), or re-tyre and profile to BR specification at a cost of at least £15K; a stark choice indeed. Meanwhile, we plough on. This summer has seen significant progress with the arrival of THE BOILER GANG. For years our Standard No.1 boiler has sat there through all weathers, untouched save for the occasional coat of red oxide primer, a wearisome reminder of a large task ahead. Then suddenly, Brian Wheeler, recently retired from Swindon Control Office and hence now with more time to spare, rounded up a team of formidable experience to tackle the task of de-tubing. The idea is that once the tubes are out, the boiler can be inspected by an expert so that we know what expenditure we shall have to face when the time comes for boiler overhaul. To get an idea of the railway experience of the new recruits, consider the following thumbnail sketches: John Mudge: apprenticed as coppersmith in Swindon Works 'A' shop, on all classes of former GWR locos as well as various BR standard types inc. 92220 Evening Star. Was first apprenticed to work on the then new diesel hydraulics (D800 and D1000 classes). When redundancies came he worked successively for British Aircraft Corporation and Bristol Cars, before rejoining the railway at Bristol Bath Road Depot as coppersmith. Retired 19/3/93 with a golden handshake from Intercity Great Western. At Bristol, John worked on all classes of the BR fleet, inc. HST's. Graham Howell: Apprenticed as fitter, turner and erector on diesels in Swindon 'A' Shop - 'Apprentice of the Year' 1970. Redundancies forced him out in 1971 - he then worked at the Lamboume Pumping Station of the Thames Valley Water Board. Came back to the Works in 1974. Worked on Adams Radial Tank (488: now at the Bluebell Rlwy) and also on 6000 KGV. Become Instructor in the Swindon apprentice training school and also Plant Inspector in the 'A' shop. Later HQ Inspector under the old Western Region and was involved in the running of steam doing GWR 150 in 1985. Now works for Intercity Great Western at Swindon Control Officer as shift engineer. Bob Judge: served his time as apprentice fitter and turner on SR in the engineering dept. before a family move (his father was a PW Inspector) took him to the north east at both Darlington Works and later Gateshead & Heaton. Worked here on all classes of former LNER locos (inc. A3, A4). A move south took Bob to Reading WR steam shed as fitter. Later became HQ Inspector before moving to Network Southeast at Old Oak Common as a Technical Inspector. From this position Bob retired 19/3/93 with the golden handshake. Right up to the finish Bob was actively involved with inspections of steam locos in connection with main line running - he is a very familiar figure at GWS Didcot. |

Photo: |

|

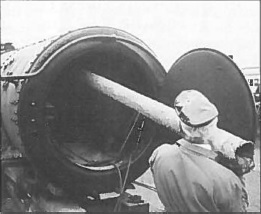

Incidentally, listening at 'snap' time to these good ol' boys telling anecdotes about their steam days is both entertaining and informative. I cannot repeat their stories here for this is a family magazine! But seriously, men like this are a disappearing breed - it is indeed fortunate that preservation societies such as QRS exist, where such men can continue to enjoy steam and may pass on their vast experience and knowledge to the up and coming generation. I digress however. The de-tubing swung into operation, with John Mudge wielding the torch. Out came the main (copper) steam pipe without the need to collapse the end. Out came the first clutch of small flues. When the boys got to the first row of large (superheater) flues, there was a problem. These flues were so thickly encrusted with concrete-hard scale that they could not be withdrawn through the tube plate. The only answer was to lift them up inside the boiler and pull them out through the aperture of the main steam pipe. The deeper down the boiler the flues, the harder became the task. Then Bob Judge made the happy discovery that the small flues were exactly the right length to construct an impromptu tripod from which to hang a chain hoist over the safety valve aperture. This device greatly eased the task of lighting the heavy flues. So, with the inside gang cutting tube ends and chiselling off the remains, and the outside gang hauling them up inside the boiler to the correct height (it took a lot of poking around down the safety valve hole to locate the wire rope of the hoist), the large flues started to see the open air (photo). Not exactly like shelling peas, judging by the expletives floating out of the smokebox, but at a steady pace nonetheless. Mind you, on one of the working days the hot sun made life difficult. Like the medieval little ease, there was no position of comfort for the outside gang on the oven-hot skin of the boiler. However one sat, kneeled or lay, a part of the anatomy soon got scorched! At the time of writing, just a handful of small flues await removal: one more working day should see them out. Then there will be the little matter of removing the scale. There is so much of it that the spaces between the flues were jammed solid with the stuff. We shall have to lower somebody down through the safety valve aperture with a bucket and rope to clear it. This person will however need to be remarkably slim, for the aperture is an oval 2'6" by 1'. Any volunteers? We have recently fitted the newly acquired (from Trevor Trembling) splasher beading to all splashers except the fire iron tunnel. This we did by using brass rivets modified by a special John Wood process. Very fine it looks, too. Another item put back was the bogie pin retaining washer, made by Colin Dinsdale to his usual high standards. Pity it cannot be seen! Next on the agenda is the replacement of the drag box, for which job we have seconded the boys from Chatham Steam Preservation. Once this is done we can replace the cab, then ... Finally, do call in the restoration shed to see the highly professional poster display on 6989 by Paul Bowen. The display makes use of what I think was an incredibly inspired idea by Alan Emmerson - to paint the boards Brunswick Green and line them out in orange. To set off the display we've painted the shed floor dark green. This is all to give the public better value for money. Now, a plea from Eric Miller The following items are required for 6989 Wightwick Hall. If any member or reader of the Quainton News knows of their whereabouts or has one would they please contact me. Similarly if any member or reader of Quainton News would like to donate or purchase one for the Hall would they please contact me. "Hope springs eternal."

|

|

Notes: Reference: |

Text © Quainton Railway Society / Photographs © Quainton Railway Society or referenced photographer

Email Webmaster

Page Updated: 27 July 2018